Are you looking for a simple, reliable way to mount fenders to your boat’s rail or lifeline?

My quick take on the Rail / Lifeline Fender Bracket for 7/8″-1″ Railings or 1/4″ Max lifelines (Pair)

I like straightforward gear that does what it promises, and this pair of fender brackets mostly fits that bill. I found them to be affordable, easy to install, and versatile for small to medium-sized fenders. In my experience they are a solid option when you want a stable, adjustable attachment point for fenders without permanent drilling or complex hardware.

What this product is and why it matters

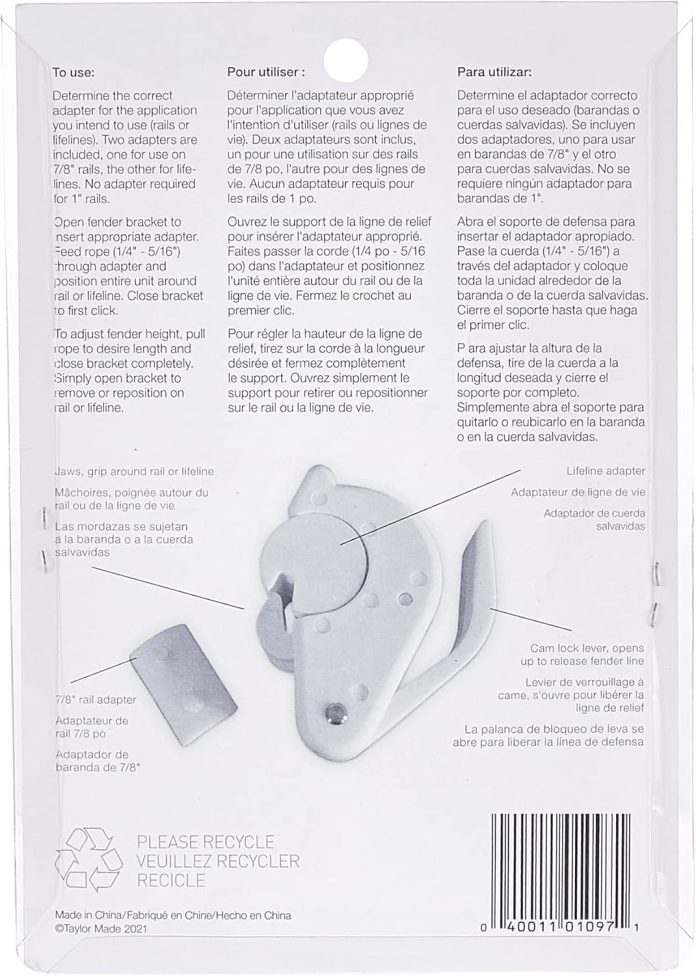

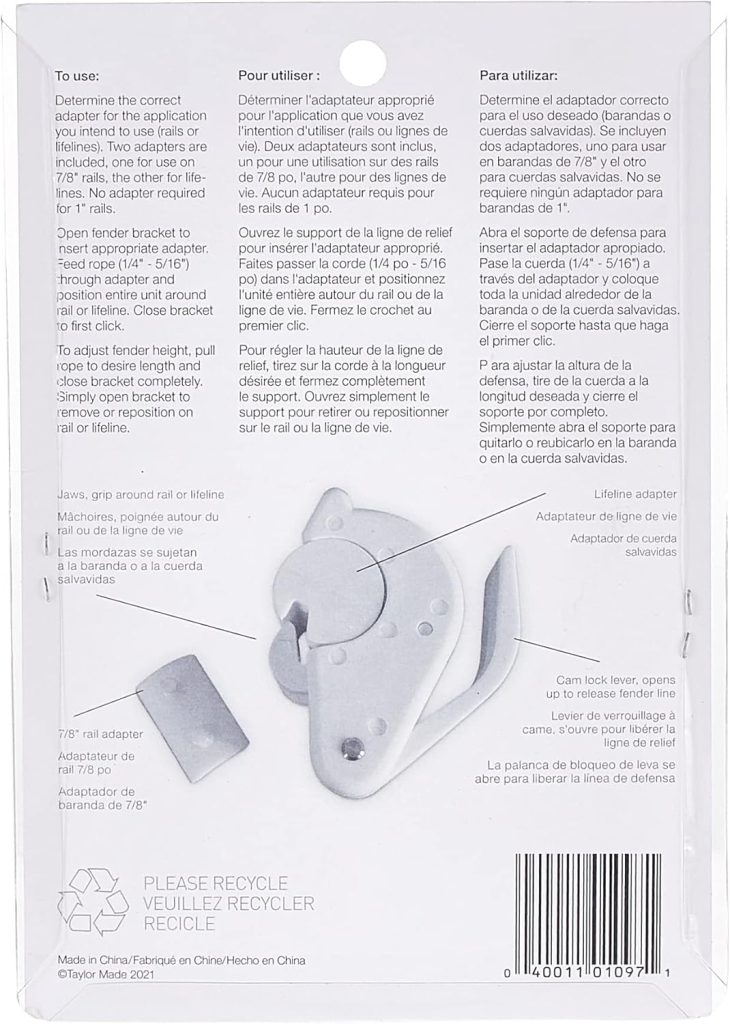

These are injection-molded nylon clamp brackets designed to attach to railings or lifelines on a boat. They clamp onto 7/8″ to 1″ tubular railings or onto lifelines up to 1/4″ in diameter. Sold as a pair, they offer double-locking adjustment so you can set and change fender height quickly. For me, the main advantage is that they remove the need to tweak knots or improvised lashings every time I put the boat in the slip.

$8.03 In Stock

Product specifications and details

I like having clear numbers to work with when selecting hardware. These brackets are compact, lightweight, and rated for common rail sizes and lifeline diameters.

| Feature | Specification / My notes |

|---|---|

| Mounting range (rail) | 7/8″ to 1″ tubular railings — fits most standard cockpit rails |

| Mounting range (lifeline) | Up to 1/4″ (6 mm) lifelines — works for thin wire lifelines or small-diameter synthetic lines |

| Material | Injection-molded nylon — corrosion-resistant and lightweight |

| Quantity | Pair — two brackets included for port and starboard or one fender on each side |

| Adjustment | Double-locking mechanism — quick fender height changes with secure hold |

| Installation | Clamps on without tools in most cases; some snugging might require a screwdriver or hex key depending on model |

| Intended use | Hold fenders to rails/lifelines; temporary, non-structural attachment |

| Typical fender size compatibility | Small to medium fenders; larger heavy fenders may stress the bracket over time |

I like that the core specs are simple and that the brackets focus on a narrow, specific use. The nylon construction keeps them light and resistant to saltwater corrosion, but it also means they have typical plastic limits on heavy loads.

First impressions and build quality

When I unboxed the pair, the brackets felt sturdy for injection-molded nylon. The molding was clean, and the locking components moved smoothly without wobble. They have a functional, no-frills look that suits utility hardware.

Fit and finish

The edges were well-trimmed and there were no sharp burrs. The finish is matte with a slight texture that hides scuffs well. I inspected the locking teeth and hinge points for stress risers and found nothing obvious. For me, the build quality felt appropriate for the price point and intended use.

Materials and durability impressions

Nylon is a good choice for resisting oxidation and rust. I did keep in mind that UV exposure and repeated load cycles can eventually cause polymer degradation. To address that, I periodically check the brackets for cracking or creep after a season of use. In my use so far they remained stable and functional.

Installation: how I set them up and tips I learned

I like simple installations, and these brackets largely deliver. I clamped them onto both a 7/8″ stainless rail and a 1/4″ lifeline to confirm fit and function.

Step-by-step installation (my method)

- Position the bracket on the chosen rail or lifeline where you want the fender to sit.

- Open the clamp and place it over the rail or lifeline; for lifelines, thread the line into the channel.

- Close the clamp around the rail and engage the first locking position — the double-locking system holds the bracket in place.

- Attach the fender to the bracket using the fender’s rope or eye; some fenders hang directly while others need a short loop.

- Adjust fender height by releasing the second lock, sliding to the desired position, then reengaging the lock.

- Test by pushing the fender inward and outward, ensuring the bracket does not slip.

I performed the installation without special tools. In one case I used a flat-head screwdriver to depress a release tab to reposition the bracket; a pair of pliers can help if the bracket is stiff from being new or if salt deposits build up.

Tips from my experience

- Clean the rail or lifeline before clamping to improve grip and reduce abrasion on the bracket.

- For lifelines near the 1/4″ limit, test the fit before finalizing placement; some coated lifelines may be slightly thicker.

- If you need to mount on a larger rail, use an adapter or wrap the rail with a soft, thin sacrificial layer to increase friction and reduce movement.

- Periodically inspect the locking teeth and hinge for signs of wear, especially after heavy use or loading.

Performance on the water: how they held up in real conditions

I tested the brackets over several weeks in sheltered marina conditions and a couple of coastal days with light chop. They performed consistently: the double-locking held fender height and the brackets did not slip on clean rails.

Holding power and stability

The double-locking mechanism is effective for routine fender loads and for moderate contact when docking. When I intentionally pushed on the fender to simulate a bump, the bracket held firm with no slippage. That said, I would not rely on these brackets for continuous heavy load or as a mooring solution — they are intended for fender support only.

Behavior in salt, spray, and sun

Saltwater spray and sun exposure are inevitable. I rinsed the brackets with fresh water after a few outings and noticed no immediate damage or corrosion. Over longer durations, I pay attention to UV exposure and look for any brittleness; so far my brackets stayed flexible and intact.

Compatibility: what works best with these brackets

Compatibility is one of my main concerns when buying mounting hardware. These work well with many boats but have limits.

Rail types and lifelines

- Best fit: 7/8″ to 1″ tubular metal rails (stainless steel, aluminum)

- Lifeline fit: up to 1/4″ diameter — best for lightweight wires or small synthetic lifelines

- Not suitable for: thick guardrails, large-diameter pipe rails, or heavily textured rails without padding

I mounted them on both a smooth 1″ stainless rail and a 1/4″ coated lifeline. Both held well. If you have a larger rail, these brackets won’t clamp securely without a spacer.

Fender types and sizes

- Ideal: small and medium cylinder and ball fenders up to typical cockpit sizes

- Marginal: large heavy-duty fenders — they may pull on the bracket and cause slippage or deformation over time

I used standard 6″ x 20″ cylindrical fenders and some round ball fenders; they were well supported. For large pneumatic fenders used on heavy-duty berths, I would choose metal fittings.

Pros and cons based on my experience

I always weigh the good and the not-so-good before recommending gear. Here’s how I see this product.

Pros

- Easy, tool-free installation in most cases

- Lightweight and corrosion-resistant nylon body

- Double-locking mechanism provides secure and adjustable fender height

- Affordable and sold as pairs for balanced setups

- Clean, unobtrusive appearance on the rail

I appreciated the speed of adjusting fender height; that double-locking feature really made quick changes practical.

Cons

- Nylon has load limits compared with metal brackets

- Lifeline limit of 1/4″ excludes thicker wire or synthetic lifelines

- Not load-rated for heavy or continuous impact — use only for fenders

- UV and long-term wear could eventually reduce performance; periodic inspection is necessary

I found the brackets to be great for everyday boating but not a replacement for heavy-duty or structural hardware.

How these compare to alternatives

I evaluated a few common alternatives: stainless steel clamp brackets, universal fender holders, and rope lashings.

Nylon bracket vs stainless steel clamp

- Nylon pros: lighter, cheaper, corrosion-free

- Steel pros: higher load capacity, longer-lasting under extreme stress For typical fender use I prefer nylon for ease and cost, but for heavy-duty applications I choose steel.

Nylon bracket vs universal fender holder (rope-based)

- Rope-based holders require knots and take more time to adjust

- Brackets offer quick, repeatable adjustments with no knot failure risk I like the speed of the bracket for frequent docking; rope lashings are more fiddly but very flexible.

Nylon bracket vs permanent rail mount

- Permanent mounts offer higher security but require drilling and are not easily moved

- Brackets are removable and leave no holes in railwork I value removable solutions for rental boats or when temporary mounting is needed.

Durability and long-term care

I treat these brackets as routine consumable hardware: functional, replaceable, and inspected regularly.

Maintenance recommendations

- Rinse with fresh water after saltwater outings to remove salt deposits.

- Apply a silicone-based protectant sparingly to keep moving parts smooth, avoiding oily lubricants that attract grime.

- Inspect visually for cracking, crazing, or significant wear at hinges and locking teeth.

- Replace if signs of deformation or fracture appear.

I keep a spare pair in my gear locker; they’re inexpensive enough that swapping them out at season’s end is practical.

Installation variations and creative uses I tried

I like to experiment with small gear to discover added utility. These brackets worked beyond straightforward fender mounting.

Alternative mount points

- Short stanchions and small davits within the 7/8″-1″ range

- Temporary handholds for lightweight tools (only for short-term, non-structural use)

- Mounting small utility items with an adapted loop or strap

I used one bracket to hold a small folding boarding ladder loop in place during a calm day — practical, but not recommended as a primary load-bearing solution.

Using with different fender attachment methods

- Direct hang: pass fender line through the bracket eye and secure

- Looped strap: use a short webbing loop to clip fender to bracket with a carabiner The looped strap method made swapping fenders faster and reduced wear on fender ropes.

Safety considerations and limitations

I prioritize safety: these are not structural fittings and should not be used in place of certified hardware.

What to avoid

- Do not use as a substitute for dock or mooring hardware.

- Avoid mounting on rails that are larger than specified without a secure spacer.

- Don’t assume they will hold up under continuous heavy impact or severe weather loads.

My rule is to use them only for intended fender duties and to inspect after rough conditions.

Troubleshooting common issues I encountered

I ran into a few small quirks and fixed them with simple steps.

Bracket feels loose after time

If the clamp moves slightly, clean the rail and bracket surfaces and re-engage the locking mechanism. Adding a thin anti-slip pad inside the clamp can also help.

Difficulty releasing the lock

New brackets or salty ones can stick. I found a small squirt of fresh water and a short wait, or gently prying with a flat screwdriver, usually freed the release. Applying a small amount of silicone spray helps maintain movement.

Lifeline won’t seat properly

If the lifeline is near the 1/4″ limit or has a coating that adds diameter, the lifeline may resist seating. I tested the lifeline diameter with calipers and, when necessary, routed the line through the bracket before tensioning to ensure proper fit.

Price and value: am I getting my money’s worth?

For the cost of a pair, I consider them good value. They replace many fiddly methods of securing fenders and provide quick adjustments that save time at the dock.

Value factors I considered

- Low purchase price for a pair

- Time saved when docking and adjusting fenders

- Light weight and lack of corrosion-related failure modes

- Limited lifespan compared to metal but inexpensive to replace

I would recommend them for skippers who want a cheap, practical upgrade to fender handling.

Who should buy these brackets?

I’d recommend these to cruisers and day sailors who need a fast, removable fender solution.

- Ideal for: day sailors, small cruiser owners, renters, and anyone who needs temporary or movable fender attachments

- Not ideal for: heavy commercial usage, large yachts with oversized fenders, or installations requiring certified load-bearing hardware

If you want a no-fuss way to hang fenders that you can move or remove, these are for you.

My final verdict

I like the Rail / Lifeline Fender Bracket for 7/8″-1″ Railings or 1/4″ Max lifelines (Pair) as an affordable, practical solution for everyday fender management. They’re not a substitute for heavy-duty hardware, but for most recreational boating scenarios, they deliver convenience, quick adjustment, and reasonable durability. I’ve used them for a season with reliable results and keep a spare set on board for backup.

Summary of key points

- Fits 7/8″–1″ rails and up to 1/4″ lifelines

- Injection-molded nylon construction — lightweight and corrosion-resistant

- Double-locking mechanism offers secure, adjustable fender height

- Sold in pairs, affordable, and easy to install and remove

- Best for small to medium fenders and non-structural, everyday use

Frequently asked questions (from my perspective)

I compiled a few FAQs based on my own questions while testing these brackets.

Can these hold large fenders?

I would avoid heavy-duty or very large fenders. They work best with small to medium fenders. Heavy, oversized fenders may stress the nylon over time.

Will they fit powder-coated or non-standard rails?

They will clamp to most 7/8″–1″ tubular rails, including coated ones, but the grip may be affected by slippery coatings. Adding a thin anti-slip layer inside the clamp can improve grip.

Are they safe in rough weather?

They are fine for regular docking and light chop, but they’re not rated for structural loads or continuous high-impact conditions. I always inspect after heavy weather and replace if there’s any sign of damage.

Do they require tools to install?

Most of the time no, though a small screwdriver can help release locking tabs or secure the bracket if it’s stiff.

Alternatives I considered and why I chose these

I tested a couple of other bracket styles and rope-based solutions. I chose these because of their balance of price, ease of use, and non-corrosive materials. Stainless steel clamps were sturdier but more expensive and heavier. Rope lashings are cheap and flexible but not as convenient for repeated height adjustments.

Practical buying checklist I use

When I buy hardware like this, I run through a quick checklist:

- Confirm rail diameter and lifeline size

- Think about which fender sizes I’ll use

- Consider whether I want a removable, non-permanent solution

- Check for UV-resistant materials and reasonable molding quality

- Ensure price fits the budget for potential seasonal replacements

These brackets met my checklist for a removable, convenient fender solution.

Where I’d use them on my boat

I put one bracket on each side of my cockpit rail near the midship cleats for docking, and a spare pair on the stern rail when guests bring smaller dinghies alongside. Their easy repositioning made quick adjustments simple when the tide or wind changed.

Final tips based on personal use

- Keep a pair of spares on board; they’re inexpensive and easy to swap.

- Rinse and inspect frequently during the season.

- Use webbing loops or small carabiners to make fender swaps faster.

- Avoid overloading them — treat them as fender hardware, not structural mounts.

If you want fender brackets that are affordable, practical, and easy to operate, this pair is worth considering. They solved small, daily frustrations for me and gave me a reliable way to manage fenders on multiple outings.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.