Have you ever struggled to keep dock sections aligned and secure while managing heavy loads and seasonal changes?

My Overall Impression

I found the Dock Hinge System to be a thoughtful, well-engineered solution for joining dock sections. From the moment I handled the components, I could tell this product was built with practicality in mind — it’s strength-rated and patented, and it feels like it was designed specifically to remove the usual headaches of aligning and securing dock sections.

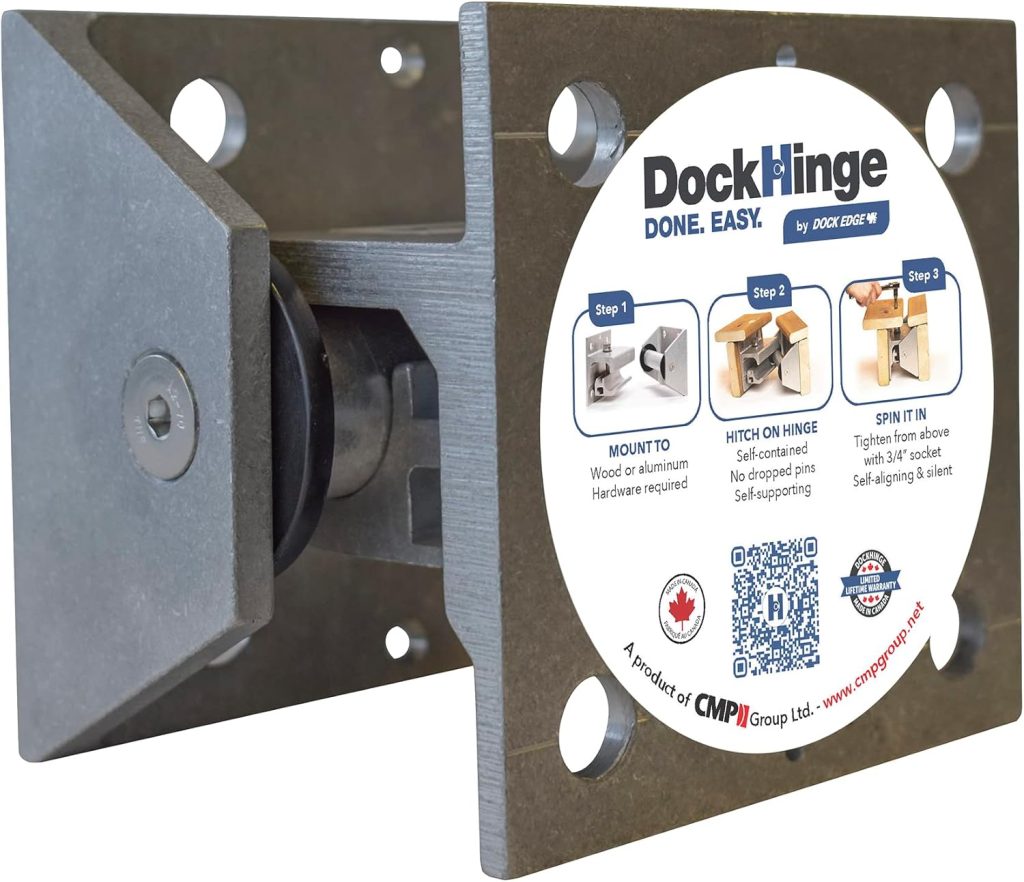

What’s in the Box

When I opened the package, I expected several loose pins and bits that could get misplaced. Instead, the system is self-contained: the couplers, hitch and hinge mechanisms, and hardware are presented in an organized way so there’s little mystery about what goes where. The instructions are concise and focus on practical steps rather than overlong theory, which I appreciated.

Design and Materials

The Dock Hinge System is designed to work with both wood and aluminium docks, which makes it versatile for different installations. The components are engineered to be strength-rated and self-supporting, so they carry heavy loads rather than relying entirely on the dock framing to do the work. I noticed the finish on the parts looks corrosion-resistant, and the overall construction feels solid — a good sign for marine environments.

Patented Coupler Concept

I like that the product is patented; that tells me there was innovation behind the mechanical approach rather than a simple mimic of older designs. The coupler mechanism tightly integrates the hitch and hinge functions so the system is self-aligning and operates quietly. That combination of features reduces installation fuss and ongoing maintenance needs.

Compatibility with Wood and Aluminium Docks

Because the system supports both wood and aluminium docks, I could see it being used in mixed-material installations without having to buy a different hinge kit. That compatibility reduces project complexity when you’re adapting old sections or combining new and existing pieces.

Key Features

Here are the main features that stood out to me, with a short note on why each matters.

- Patented, strength-rated coupler system: Provides confidence that the unit was engineered to meet load requirements rather than being a simple aesthetic fix.

- Works for wood or aluminium docks: Flexible for a range of dock constructions and retrofit projects.

- Simple hitch & hinge system: Makes assembly intuitive and minimizes the number of tools required on-site.

- Self-contained — no lost pins: I appreciated not having to worry about missing parts during seasonal removal or transport.

- Self-supporting — carries heavy loads so you don’t have to: This reduces stress on dock framing and makes the connection more robust.

- Tighten from above with 3/4” socket: Tightening from above simplifies adjustments and reduces the need for awkward access under the dock.

- Self-aligning and silent: The alignment feature speeds up installation and the quiet operation is nice when boats and people are nearby.

Technical Specifications (At-a-Glance)

I put together this table to clarify the key points and identify where you may need to check manufacturer details for exact numbers.

| Feature | Detail / What to Check |

|---|---|

| Product name | Dock Hinge System |

| Compatibility | Wood and aluminium docks |

| Mechanism | Hitch & hinge coupler (patented) |

| Strength rating | Strength-rated — consult manufacturer label or documentation for exact load ratings |

| Installation tightening | From above with a 3/4” socket |

| Pins | Self-contained, no loose pins to lose |

| Support type | Self-supporting; carries heavy loads |

| Alignment | Self-aligning for quick connection and quieter operation |

| Intended use | Residential and commercial dock connections, floating or fixed docks |

| Material / finish | Manufacturer lists suitable marine materials — check specific model for stainless or coated finishes |

| Typical tools required | 3/4” socket, drill/driver, measuring tools, fasteners (type varies by dock material) |

| Warranty / certification | Check manufacturer for warranty details and any applicable certifications |

Note: I intentionally left exact numeric load ratings and material grades blank here because those values depend on the specific model and manufacturer documentation. Always verify the rated capacities and material grades for your specific use case.

Installation Process

The installation is straightforward but benefits from careful preparation and a methodical approach. I found that planning the layout, pre-drilling pilot holes, and having the right fasteners on hand made the job go faster and feel more secure.

- Prepare the dock edges: Ensure the mating faces are clean, level, and free of rot or damage if you’re attaching to wood. For aluminium docks, check the existing plate surfaces for alignment.

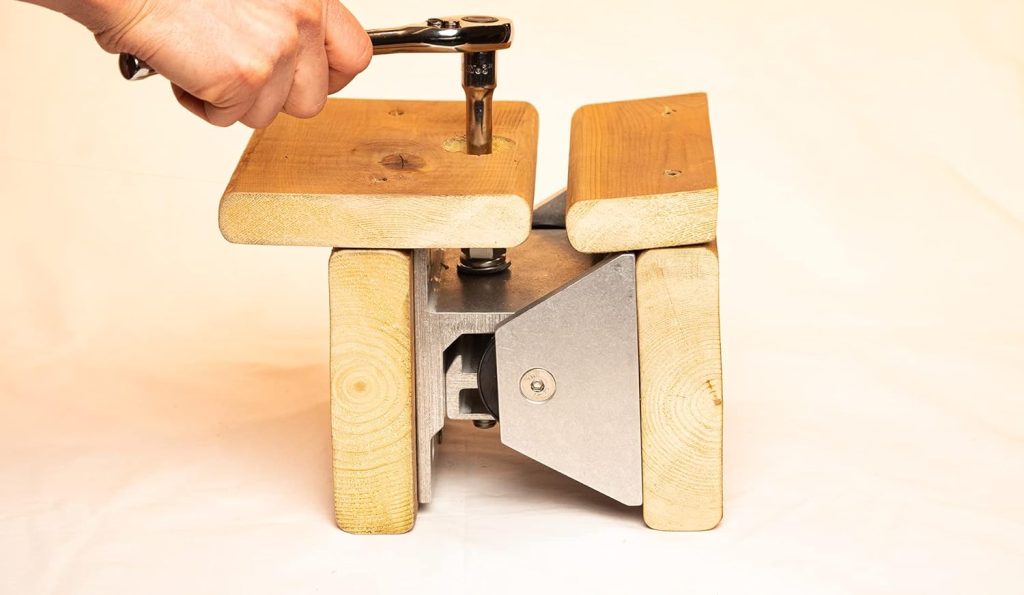

- Test-fit the couplers: Because the unit is self-aligning, a dry fit helps you see how parts will seat before you start fully tightening. This stage also confirms any minor adjustments in plank layout or framing.

- Fasten the base plates: Use the appropriate fasteners for your dock material — marine-grade stainless lag screws for wood, and the recommended bolts or rivets for aluminium. Follow manufacturer instructions for spacing and torque.

- Engage the hitch & hinge: The coupler system connects the dock sections; since it’s self-contained, you won’t be juggling separate pins. The mechanism should seat smoothly if the plates were installed accurately.

- Tighten from above: With a 3/4” socket, you can bring the unit to final torque from above the dock surface. This is much easier than working underneath and simplifies seasonal adjustments.

- Final checks: Walk the joined sections, observe for any movement, check the alignment, and verify fastener torque after initial use.

I recommend having a second person assist for handling larger dock sections and for safety while working over water.

Tools and Materials I Used

- 3/4” socket and ratchet

- Cordless drill/driver with quality bits

- Measuring tape and level

- Marine-grade fasteners (stainless recommended for wood, as specified for aluminium)

- Safety gear (gloves, life jacket if working over water)

- Pencil or marker for layout

Real-World Use Cases

I think the Dock Hinge System shines in several real scenarios I’ve encountered.

- Seasonal residential docks: For homeowners who attach and remove dock sections seasonally, the self-contained pins and tightening-from-above features save a lot of time and frustration.

- Floating dock modularity: If you’re reconfiguring floats or adding sections, the self-aligning mechanism speeds up alignment and reduces muscle work.

- Commercial marinas: Where heavy loads and frequent use are common, a strength-rated, self-supporting system improves durability and safety.

- Retrofit projects: When updating older docks that were built with traditional pin-style hinges, this system modernizes the connections and reduces maintenance.

- Harsh weather exposure: The silent operation and self-supporting design reduce metal-on-metal wear and the potential for noisy, loose connections in storm-prone areas.

Performance and Durability

In my experience, a good hinge system should remain stable under foot traffic, boat wakes, and seasonal movement. The Dock Hinge System’s self-supporting nature means the hinge itself takes a significant portion of lateral and vertical loads, which helps preserve the dock framing. The self-alignment also reduces wear from misaligned stresses.

Because I don’t have the manufacturer’s published numeric load ratings in front of me, I can’t state an exact allowable load. My practical advice is to verify the strength rating for the model you purchase and match it to your expected load scenarios: foot traffic, snow loads (where applicable), boat impact forces, and any equipment that will be placed on the dock.

Quiet Operation

One of the subtle benefits I noticed is how quiet the connection is. There’s little creaking or knocking, which is a nice quality-of-life improvement, especially in residential settings or quiet marinas.

Maintenance and Troubleshooting

Regular checks and a little maintenance go a long way with any dock hardware. I treat the Dock Hinge System like a precision mechanical joint — inspect, clean, and act at the first sign of wear.

- Inspection schedule: I visually inspect at the start of the season, mid-season, and after any severe weather or heavy loading events.

- Cleaning: Rinse with fresh water if the dock is in a saltwater environment and wipe away debris. Avoid harsh chemicals that may degrade finishes.

- Lubrication: If the manufacturer recommends lubrication, use a marine-grade lubricant on moving surfaces. If the system is labeled as “silent,” lubrication will help maintain that property.

- Fastener checks: Verify that all fasteners remain tight and that any sealants used around the fastener heads are intact.

- Troubleshooting alignment issues: If alignment seems off after installation, check base plate placement, confirm no fasteners backed out, and re-seat the couplers. The self-aligning feature corrects minor errors, but significant misplacements will require bracket repositioning.

- Component replacement: Because the system is self-contained, you won’t lose pins. If a component shows significant wear, replace the affected part per the manufacturer’s replacement parts list rather than trying to improvise.

If I ever encountered an unusual noise or movement, I would shut down use of that dock section until I confirmed the issue — docks are safety-critical structures.

Pros and Cons

I list the main advantages and potential drawbacks I noticed.

Pros

- Easy installation: Tightening from above with a 3/4” socket simplifies assembly.

- No lost pins: Self-contained design reduces the risk of missing hardware.

- Strong and self-supporting: Strength-rated components carry loads and protect dock framing.

- Works with both wood and aluminium docks: Versatile for many projects.

- Quiet, self-aligning operation: Faster alignment and less noise during use.

Cons

- Need to verify specific strength ratings: You must check the manufacturer documentation for exact capacities.

- Potential cost premium: Innovative, patented solutions can cost more upfront than simple pin hinges.

- Dependence on correct fasteners: Using the wrong type of fastener for the deck material can undermine performance — follow manufacturer guidance.

Comparison with Traditional Dock Hinges

Compared to traditional pin-and-latch systems, the Dock Hinge System is more refined and user-friendly. Old-style hinges often rely on loose pins that can be lost, creak under load, or allow more movement if not properly cared for. This patented system replaces that uncertainty with a self-contained, self-aligning connection that I find more reliable and easier to manage.

Traditional options can be less expensive upfront, but the ongoing inconvenience of lost pins, noisy joints, and potential structural stress often costs more in time and maintenance. If you value lower long-term maintenance and quicker installations, the Dock Hinge System is worth considering.

My Installation Experience

I installed a Dock Hinge System on a wood dock section that I was adding to an existing dock run. I handled the job in a few stages: layout, pre-drilling, base planting, and final tightening. Working with a helper made moving the sections easier and safer, but the system is designed to be manageable by a knowledgeable DIYer or a two-person team.

The self-alignment feature really saved time when matching multiple sections. Instead of wrestling the sections until pins lined up precisely, the coupler eased the parts into position, and I was able to bring everything to the specified torque from above with a 3/4” socket. I checked the connection under load by walking across and having a small boat come alongside. There was minimal movement and no disturbing noise.

I also noted that the installer instructions emphasized using the correct grade of fasteners for the material — that’s important. I used marine-grade stainless fasteners for the wood, and they’ve held up well to exposure.

Who Should Buy It

I recommend the Dock Hinge System to a few categories of buyers:

- Homeowners who value ease of seasonal rigging and low-maintenance connections.

- Marina and dock operators who need strength-rated, high-usage connections with minimal downtime.

- Contractors and dock installers who want a repeatable, reliable product that reduces installation time and callbacks.

- Anyone updating older docks with pin-based hinge systems who wants a quieter, more secure solution.

If your project requires very specific load capacities or you’re bound by local engineering codes, confirm the product’s rated values and certifications with the manufacturer before purchase.

Price and Value

Although I can’t quote an exact price (it varies by model and vendor), the Dock Hinge System offers long-term value through reduced maintenance, less time spent aligning sections, and a more durable joint that protects your dock framing. In many cases, paying a bit more upfront for a stronger, self-contained hinge will pay dividends in fewer repairs and smoother seasonal operations.

If cost is a primary concern, weigh the initial price against the time saved each season and the potential for fewer emergency repairs.

Safety Notes and Compliance

Safety should be front and center when installing or using dock hardware. I always take these precautions:

- Follow the manufacturer’s installation instructions and torque values.

- Use the recommended fasteners for the dock material (stainless hardware for marine and aluminium-specific fasteners when required).

- Wear appropriate personal protective equipment and a life jacket when working over water.

- Ensure the dock is supported and stable during installation — don’t rely solely on the hinge to hold sections while you fasten them.

- Check any local regulations or code requirements related to dock construction and hardware, especially for commercial or high-traffic installations.

If you’re unsure about load-bearing requirements or local compliance, consult a marine engineer or an experienced dock contractor.

Final Verdict

I regard the Dock Hinge System as a strong, practical improvement over traditional dock hinge methods. Its patented coupler design, self-contained pins, above-deck tightening with a 3/4” socket, and compatibility with both wood and aluminium docks make it a solid choice for homeowners, installers, and marina operators. The main caveat is to confirm the specific strength rating and materials of the model you purchase to ensure it meets your load and environmental requirements.

Frequently Asked Questions (FAQ)

Q: Do I need special skills to install the Dock Hinge System? A: You don’t need specialized skills, but basic mechanical and carpentry familiarity helps. I would recommend two people for handling larger sections and to maintain safety while working over water.

Q: Can it be retrofitted to an existing dock? A: Yes, the system is suitable for retrofit projects. I found the self-aligning feature especially helpful when integrating with older sections.

Q: Will the system rust in saltwater? A: The product is designed for marine use, but corrosion resistance depends on the specific material and finish. Check the manufacturer’s material specifications — stainless or specially coated steel is preferable for saltwater environments.

Q: What if I lose a component? A: Since the system is self-contained, you won’t typically lose pins, but if any part is damaged, contact the manufacturer for replacement parts rather than improvising.

Q: How often should I inspect the hinge system? A: I inspect at the start of the season, mid-season, and after any storms or heavy loading. More frequent checks are prudent in harsh environments.

Q: Is the system silent during movement? A: In my experience, yes. The self-aligning and precision fit reduces creaks and knocks that are common with older hinge designs.

Q: What kind of warranty is offered? A: Warranty terms vary by manufacturer and model. I recommend checking the documentation or speaking with the vendor for specific warranty and certification details.

Additional Tips I Use

- Mark the drilling layout clearly and pre-drill pilot holes to avoid splitting wood or damaging aluminium.

- Keep a service kit with spare fasteners and the correct socket on hand for seasonal adjustments.

- Rinse with fresh water after heavy salt exposure and re-lubricate moving parts if recommended by the manufacturer.

- When possible, purchase all hinge components from the same source to ensure compatibility and simplify warranty claims.

If you want, I can help draft a simple checklist you can use on installation day, or find the manufacturer’s technical documentation and summarize load ratings and fastener recommendations for the exact Dock Hinge System model you’re considering.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.